An expander is a device that is used to increase the size or capacity of something. It is commonly used in various fields such as engineering, construction, and manufacturing. The purpose of an expander is to allow for expansion or enlargement of a particular object or system.

One of the main purposes of an expander is to accommodate growth or changes in a system. For example, in mechanical engineering, expanders are used in machines and equipment to allow for thermal expansion. As materials heat up, they expand, and an expander helps to prevent damage by allowing for this expansion without causing any structural issues.

Another purpose of an expander is to improve efficiency and performance. In the field of fluid dynamics, expanders are used in turbines and compressors to increase the pressure and flow rate of fluids. By using an expander, the energy of the fluid can be harnessed more effectively, leading to improved performance and efficiency.

What is an Expander?

An expander is a mechanical device that is used to increase the size or volume of a material or substance. It works by applying force or pressure to the material, causing it to expand or stretch. Expanders are commonly used in various industries and applications, including manufacturing, construction, and medical fields.

Expander devices are designed to be versatile and adaptable, allowing them to be used for a wide range of purposes. They can be used to stretch or enlarge materials such as metal, plastic, rubber, or even biological tissues. The expansion process can be controlled and adjusted to achieve the desired size or shape.

Expander devices come in different forms and sizes, depending on the specific application and requirements. They can be manual or automated, and they may use different mechanisms to generate the necessary force or pressure. Some expanders use hydraulic or pneumatic systems, while others rely on mechanical or electrical mechanisms.

Overall, expanders play a crucial role in various industries and applications by enabling the expansion and stretching of materials. They offer a reliable and efficient way to increase the size or volume of a substance, allowing for greater flexibility and versatility in manufacturing processes and other applications.

Definition of an Expander

An expander is a mechanical device that is used to increase the size or volume of a material or substance. It works by applying force or pressure to the material, causing it to expand and occupy a larger space. Expanders are commonly used in various industries, including manufacturing, construction, and healthcare.

Expanders can be used on a wide range of materials, including metals, plastics, and rubber. They are designed to provide controlled and precise expansion, allowing for the desired increase in size without causing damage to the material.

Expanders come in different shapes and sizes, depending on the specific application. They can be manual or powered by hydraulic, pneumatic, or electric systems. Some expanders are designed to be portable and handheld, while others are larger and require a fixed installation.

Overall, expanders play a crucial role in many industries, enabling the efficient and accurate expansion of materials. They are essential tools for achieving precise measurements, improving product quality, and ensuring the proper fit and functionality of various components.

How Does an Expander Work?

An expander is a mechanical device that is used to increase the size or volume of a material or structure. It works by applying force or pressure to the material, causing it to expand or stretch. There are several different types of expanders, each with its own unique mechanism for achieving expansion.

One common type of expander is a hydraulic expander. This type of expander uses hydraulic pressure to expand a material. It consists of a cylinder filled with hydraulic fluid and a piston that is pushed into the cylinder, forcing the fluid to move and expand the material. Hydraulic expanders are often used in industries such as construction and manufacturing.

Another type of expander is a mechanical expander. This type of expander uses gears, levers, or other mechanical mechanisms to apply force or pressure to the material. Mechanical expanders are often used in applications where precise control over the expansion process is required.

Expanders can be used in a variety of applications. For example, they can be used to increase the size of pipes or tubes, allowing for the passage of larger volumes of fluid. They can also be used to stretch materials such as metal or plastic, making them more malleable and easier to work with. Additionally, expanders can be used in medical applications, such as orthodontics, where they are used to widen the jaw or palate.

Overall, expanders are versatile tools that can be used in a wide range of applications. They work by applying force or pressure to a material, causing it to expand or stretch. Whether it’s increasing the size of a pipe or tube, stretching a material, or widening the jaw, expanders play a crucial role in many industries and applications.

Different Types of Expanders

Expanders are versatile devices that come in various types, each designed for specific applications and requirements. Here are some of the different types of expanders:

1. Mechanical Expanders

Mechanical expanders use mechanical force to expand or stretch materials. They are commonly used in industries such as construction, manufacturing, and automotive. Mechanical expanders can be manual or powered by hydraulic or pneumatic systems.

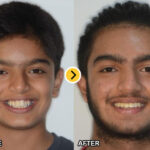

2. Dental Expanders

Dental expanders are orthodontic devices used to widen the upper jaw or correct dental misalignments. They are commonly used in orthodontic treatments to create space for crowded teeth or correct bite problems. Dental expanders can be fixed or removable, depending on the patient’s needs.

3. Heat Expanders

4. Rubber Expanders

Rubber expanders are flexible devices made of rubber or elastomeric materials. They are commonly used in industries such as oil and gas, mining, and agriculture. Rubber expanders are used for sealing, gripping, or creating a tight fit between two surfaces. They can also be used for vibration isolation or shock absorption.

5. Tissue Expanders

Tissue expanders are medical devices used in reconstructive surgeries or plastic surgeries. They are used to stretch the skin and underlying tissues to create extra skin for surgical procedures. Tissue expanders are often used in breast reconstruction surgeries or to correct defects caused by burns or trauma.

6. Airway Expanders

Benefits of Using an Expander

An expander is a versatile tool that offers several benefits in various applications. Here are some of the key advantages of using an expander:

1. Improved Efficiency: Expanders are designed to increase the efficiency of systems by recovering energy that would otherwise be wasted. They can be used in heat recovery systems to capture and reuse heat from exhaust gases, reducing the overall energy consumption of the system.

2. Increased Capacity: By expanding gases or fluids, an expander can help increase the capacity of a system. This is particularly useful in applications such as power generation, where expanders can be used to extract additional power from existing systems.

3. Cost Savings: The use of an expander can lead to significant cost savings in various ways. By recovering energy that would otherwise be lost, expanders can help reduce energy costs. Additionally, expanders can help optimize the performance of systems, leading to improved efficiency and reduced maintenance costs.

4. Environmental Benefits: Expanders play a crucial role in promoting sustainability and reducing environmental impact. By recovering energy that would otherwise be wasted, expanders help reduce greenhouse gas emissions and contribute to a cleaner environment.

5. Versatility: Expanders can be used in a wide range of applications across various industries. They can be integrated into different systems, such as power plants, chemical plants, and refrigeration systems. This versatility makes expanders a valuable tool for engineers and designers.

6. Improved System Performance: By expanding gases or fluids, an expander can help optimize the performance of a system. This can lead to improved reliability, increased efficiency, and enhanced overall system performance.

7. Enhanced Energy Recovery: Expanders are highly effective in recovering energy from waste streams or low-pressure sources. They can be used to extract energy from sources such as exhaust gases, steam, or hot water, and convert it into usable power or heat.

8. Reduced Carbon Footprint: By recovering energy and improving system efficiency, expanders help reduce the carbon footprint of various industries. This is especially important in sectors such as power generation, where reducing emissions is a top priority.

9. Longevity and Durability: Expanders are built to withstand high pressures, temperatures, and harsh operating conditions. They are designed to be durable and reliable, ensuring long-term performance and minimal downtime.

10. Customization Options: Expanders can be customized to meet specific requirements and operating conditions. This allows engineers to design expanders that are tailored to the needs of their applications, ensuring optimal performance and efficiency.

Overall, the use of an expander offers numerous benefits, including improved efficiency, increased capacity, cost savings, environmental benefits, versatility, improved system performance, enhanced energy recovery, reduced carbon footprint, longevity and durability, and customization options. These advantages make expanders an essential tool in various industries and applications.

Applications of Expanders

Expanders have a wide range of applications in various industries due to their ability to increase the size or volume of a substance. Here are some common applications of expanders:

- Oil and Gas Industry: Expanders are commonly used in the oil and gas industry for gas processing and natural gas liquefaction. They are used to increase the pressure and volume of natural gas, making it easier to transport and store.

- Power Generation: Expanders play a crucial role in power generation facilities. They are used in steam turbines to extract energy from the steam, which is then converted into electrical energy. Expanders are also used in geothermal power plants to convert the energy from hot water or steam into electricity.

- Air Compression: Expanders are used in air compression systems to increase the pressure and volume of air. This is important in applications such as air conditioning, refrigeration, and pneumatic tools.

- Chemical Processing: Expanders are widely used in chemical processing plants. They are used to increase the volume and pressure of gases and liquids, facilitating various chemical reactions and processes.

- Food and Beverage Industry: Expanders are used in the food and beverage industry for various purposes. They are used in food processing to increase the volume of dough, batter, and other food products. Expanders are also used in the beverage industry for carbonation and to increase the volume of beverages.

- Wastewater Treatment: Expanders are used in wastewater treatment plants to increase the volume and pressure of gases and liquids. They help in the aeration process, where oxygen is introduced into the wastewater to promote the growth of aerobic bacteria that break down organic matter.

- Medical Applications: Expanders find applications in the medical field as well. They are used in medical devices such as prosthetics and implants to gradually expand tissues or bones. Expanders are also used in certain dental procedures to create space for dental implants.

These are just a few examples of the wide range of applications of expanders. The versatility and effectiveness of expanders make them an essential tool in various industries.

Factors to Consider when Choosing an Expander

When choosing an expander, there are several important factors to consider. These factors will help you determine the most suitable expander for your specific needs and ensure optimal performance. Here are the key factors to keep in mind:

1. Application

2. Operating Conditions

3. Flow Rate and Capacity

4. Efficiency and Performance

When selecting an expander, it’s essential to consider its efficiency and performance characteristics. Look for an expander that offers high efficiency, low energy consumption, and reliable performance. This will ensure that your system operates optimally and minimizes any potential downtime or maintenance issues.

5. Maintenance and Serviceability

Consider the maintenance requirements and serviceability of the expander. Look for an expander that is easy to maintain and service, with readily available spare parts and a reliable support network. This will help minimize downtime and ensure that your expander remains in good working condition for an extended period.

6. Cost and Budget

By considering these factors when choosing an expander, you can ensure that you select the most suitable equipment for your specific needs. This will result in optimal performance, efficiency, and reliability, ultimately leading to improved productivity and cost savings for your operation.

Common Features of Expanders

Expanders are versatile tools that can be used in a variety of applications. They are designed to increase the size or volume of a material or substance. Here are some common features of expanders:

| Feature | Description |

|---|---|

| Adjustable Size | Many expanders have adjustable settings, allowing users to control the degree of expansion. This is useful for achieving precise results and accommodating different materials. |

| Multiple Expansion Modes | Some expanders offer multiple expansion modes, such as radial and axial expansion. This allows for greater flexibility in expanding different types of materials and achieving specific expansion patterns. |

| Easy Operation | Expanders are designed to be user-friendly and easy to operate. They often feature intuitive controls and ergonomic designs, making them accessible to both experienced professionals and beginners. |

| Durable Construction | Expanders are typically made from high-quality materials, such as stainless steel or durable plastics. This ensures their longevity and resistance to wear and tear, even in demanding industrial environments. |

| Safety Features | Many expanders are equipped with safety features to protect users and prevent accidents. These may include safety locks, emergency stop buttons, or automatic shut-off mechanisms. |

| Portability | Some expanders are designed to be portable, allowing users to easily transport them to different work sites. This is especially beneficial for professionals who need to expand materials in various locations. |

| Compatibility | Expanders are often compatible with a wide range of materials, such as metals, plastics, and composites. This versatility makes them suitable for use in various industries, including manufacturing, construction, and automotive. |

| Low Maintenance | Expanders typically require minimal maintenance. Regular cleaning and lubrication are usually sufficient to keep them in optimal working condition. Some models may also feature self-cleaning mechanisms. |

| Accessories | Many expanders come with a range of accessories, such as interchangeable heads or expansion dies. These accessories allow users to customize the expansion process and adapt to different materials and applications. |

| Cost-Effective | Expanders offer a cost-effective solution for expanding materials. They eliminate the need for expensive and time-consuming manual methods, such as hammering or stretching, and can significantly reduce labor costs. |

Maintenance and Care for Expanders

Maintaining and caring for expanders is essential to ensure their longevity and optimal performance. Regular maintenance and proper care can help prevent malfunctions, extend the lifespan of the equipment, and ensure safe operation. Here are some important guidelines to follow:

1. Regular Cleaning

Regularly clean the expander to remove any dirt, dust, or debris that may accumulate on the surface. Use a soft cloth or brush to gently wipe the exterior of the equipment. Avoid using harsh chemicals or abrasive materials that can damage the expander.

2. Lubrication

Proper lubrication is crucial to keep the moving parts of the expander functioning smoothly. Refer to the manufacturer’s instructions for the recommended lubricant and frequency of lubrication. Apply the lubricant to all the necessary areas, such as bearings and gears, to ensure optimal performance.

3. Inspection

Regularly inspect the expander for any signs of wear, damage, or loose components. Check for any leaks, unusual noises, or vibrations during operation. If any issues are detected, take immediate action to address them to avoid further damage or safety hazards.

4. Calibration

Periodically calibrate the expander to ensure accurate and consistent performance. Follow the manufacturer’s instructions for the calibration process or consult a professional if needed. Calibration helps maintain the precision and reliability of the expander.

5. Storage

If the expander is not in use for an extended period, proper storage is essential. Clean the equipment thoroughly before storing it in a dry and secure location. Protect the expander from dust, moisture, and extreme temperatures that can cause damage.

6. Training

Ensure that the operators and maintenance personnel receive proper training on the operation, maintenance, and safety procedures of the expander. This will help prevent accidents, minimize errors, and maximize the lifespan of the equipment.

By following these maintenance and care guidelines, you can ensure that your expander operates efficiently and reliably for years to come. Regular maintenance and proper care are crucial to maximize the performance and lifespan of the equipment.

Frequently Asked Questions about Expanders

1. How often should I perform maintenance on my expander?

2. Can I use any type of lubricant for my expander?

3. What are some common signs of expander malfunction?

4. How can I ensure the safety of my expander?

5. Can I troubleshoot minor issues with my expander on my own?

6. Are expanders suitable for all applications?

Expander Safety Precautions

1. Wear Protective Gear

Always wear appropriate personal protective equipment (PPE) when operating an expander. This may include safety glasses, gloves, ear protection, and steel-toed boots. PPE will help protect you from potential hazards such as flying debris, noise, and accidental contact with moving parts.

2. Read the User Manual

Before using an expander, thoroughly read and understand the user manual provided by the manufacturer. The manual will provide important information on safe operation, maintenance, and troubleshooting procedures. Following the manufacturer’s instructions will help prevent accidents and equipment damage.

3. Check for Proper Installation

Prior to using an expander, ensure that it is properly installed and securely mounted. Check that all bolts, nuts, and connections are tightened according to the manufacturer’s specifications. A loose or improperly installed expander can lead to accidents or equipment failure.

4. Inspect the Equipment

Regularly inspect the expander for any signs of wear, damage, or malfunction. Check for loose or damaged parts, leaks, and abnormal noises. If any issues are detected, discontinue use and have the equipment inspected and repaired by a qualified professional.

5. Use in a Well-Ventilated Area

When operating an expander, ensure that you are in a well-ventilated area. Expanders can generate fumes, dust, or heat, depending on the type and application. Adequate ventilation will help prevent the buildup of potentially harmful substances and maintain a safe working environment.

6. Follow Proper Start-Up and Shutdown Procedures

Always follow the correct start-up and shutdown procedures for the specific expander model you are using. This may include checking fluid levels, priming the pump, and allowing the equipment to cool down before shutting it off. Proper procedures will help prevent accidents and extend the lifespan of the equipment.

7. Keep a Clean and Organized Workspace

Maintain a clean and organized workspace when using an expander. Remove any unnecessary clutter or obstacles that may pose a tripping hazard. Keep the work area well-lit and free from oil, grease, or other slippery substances that could cause accidents.

8. Avoid Overloading the Expander

Do not exceed the recommended capacity or load limits of the expander. Overloading the equipment can lead to excessive strain, premature wear, and potential failure. Always check the manufacturer’s specifications to ensure that the expander is being used within its safe operating limits.

9. Properly Store and Transport the Expander

When the expander is not in use, store it in a clean and dry area away from direct sunlight and extreme temperatures. If the equipment needs to be transported, secure it properly to prevent damage or shifting during transit. Follow the manufacturer’s guidelines for storage and transportation.

By following these expander safety precautions, you can minimize the risk of accidents, injuries, and equipment damage. Always prioritize safety and consult the manufacturer or a qualified professional if you have any concerns or questions regarding the safe use of an expander.

Expander Troubleshooting

When using an expander, you may encounter certain issues that can affect its performance. Here are some common troubleshooting tips to help you resolve these problems:

1. Low Expansion Capacity:

If you notice that your expander is not expanding to its full capacity, check if the expansion chamber is properly sealed. Ensure that there are no leaks or blockages in the system. Also, make sure that the expander is operating at the correct temperature and pressure settings.

2. Noisy Operation:

If your expander is making unusual noises, it could be due to loose or worn-out components. Check all the connections and tighten any loose bolts or screws. If the noise persists, it may indicate a more serious issue, and you should consult a professional for further inspection.

3. Inconsistent Expansion:

If you experience inconsistent expansion results, it could be caused by variations in the input gas or liquid flow rate. Ensure that the flow rate is consistent and within the recommended range. Additionally, check if the expander blades or vanes are clean and free from any debris or buildup that could hinder their movement.

4. Overheating:

If your expander is overheating, it may be due to excessive friction or inadequate cooling. Check if the lubrication is sufficient and if the cooling system is functioning properly. Clean any cooling fins or filters that may be obstructed by dirt or debris.

5. Vibrations:

Excessive vibrations can affect the performance and lifespan of an expander. Inspect all the mounting points and ensure that they are secure. If vibrations persist, it could indicate a misalignment or imbalance issue, which should be addressed by a professional.

6. Failure to Start:

If your expander fails to start, check if the power supply is connected and functioning correctly. Inspect the control panel for any error codes or indicators that may provide insight into the issue. If the problem persists, contact the manufacturer or a qualified technician for assistance.

7. Excessive Wear:

If you notice excessive wear on the expander components, it may be a sign of misalignment, inadequate lubrication, or operating beyond the recommended limits. Regularly inspect and maintain your expander to prevent premature wear and ensure optimal performance.

By following these troubleshooting tips, you can address common issues with expanders and ensure their efficient and reliable operation.

Dr. Fidel Cann: Esteemed orthodontist with a lifelong dedication to enhancing smiles and oral health. Pioneering expertise, compassionate care.